Need an installation in your area? Our Global Dealers are our Partners. 480-809-7634

MISTING SYSTEM MAINTENANCE

PUMP SYSTEM OIL CHANGE

PUMP SYSTEM OIL CHANGE

PUMP SYSTEM OIL CHANGE

Pump oil should be changed after the first 50 hours of operation and then every 500 hours or three months which ever comes first. If the equipment is used in very severe conditions (commercial) the oil may have to be changed sooner.

NOZZLE CLEANING

PUMP SYSTEM OIL CHANGE

PUMP SYSTEM OIL CHANGE

This service requires disassembling the misting system nozzle and unscrewing the nozzle tip from the housing then soaking in our hydrochloric solution for 15 min. Reassemble the nozzles.

FILTER MEDIA CHANGE

PUMP SYSTEM OIL CHANGE

SYSTEM FLUSH/BELT INSPECTION

Wash out the filter bowl thoroughly. Replace with a clean filter cartridge. Remove the O-ring from the filter housing and apply a coat of lubricant; as you re-install it back, ensure that it is seated properly on the pump and allow for a proper seal of the filter housing.

SYSTEM FLUSH/BELT INSPECTION

SYSTEM FLUSH/BELT INSPECTION

SYSTEM FLUSH/BELT INSPECTION

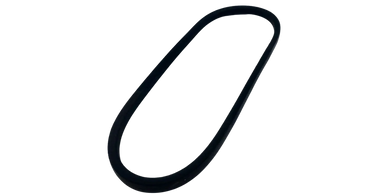

Release of 3 nozzles on the end of each zone of the atomizing tube and flush the system of any debri. Pulley drive systems, ensure that the belts have proper tension, that the pulleys are secure, and that any belt guards are properly secured.

PUMP SAVER AND CLEANING

SYSTEM FLUSH/BELT INSPECTION

NOZZLE REPLACEMENT/REPAIR

Protect your misting pump and other components during cold winter months when it is not in use! This service clears out hard water mineral deposits, preserves pump seals and pistons, and removes water to avoid freezing.

NOZZLE REPLACEMENT/REPAIR

SYSTEM FLUSH/BELT INSPECTION

NOZZLE REPLACEMENT/REPAIR

The nozzle springs, viton ball and O-rings should be inspected to ensure optimal flow and performance.

Copyright © 2025 Precision Mist - All Rights Reserved.

MESA LOCATION:

60 W BASELINE RD

MESA, AZ 85210

480-809-7634

www.PrecisionMist.com

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.